Overview

What is LZZG Filter Press?

LZZG filter press is a piece of sludge dewatering equipment that separates liquids and solids using pressure filtration in the sludge management. When working, slurry will be pumped into press chambers and dewatered with pressure. Each unit need to be designed based on the types of slurry as well as the volumes.

Our filter presses are supplied for a wide application in municipal & industrial wastewater treatment. Feed mud concentration always be 30%-40%, then mud will become mud cake and the humidity is around 20% after processed. LZZG filter press is a kind of Plate and Frame Filter Press, some now call it as “Chamber Filter Press”. Typically, no flocculant are needed to help dewatering on a plate filter press.

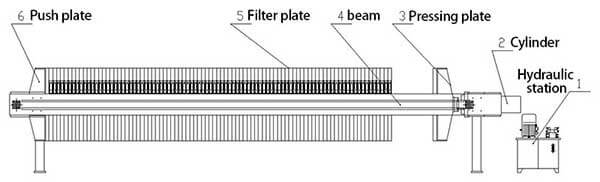

Filter Press Structure:

The 8 main components of LZZG filter press:

- Hydraulic Station (Hydraulic Systems),

- Cylinder, Pressing Plate, Beam,

- Filter Plates, Push Plate,

- Filter Cloths, Feed Pump.

The terms used to describe the components may vary slightly from different manufacturers, but the main function still remain the same.

LZZG is professional manufacturer of filter presses: Automatic Filter Press, Recessed Plate Filter Press and Membrane Filters are all on sale, inquiry us for filter press price now.

Working Site

Filter press can be built in many sizes and used for solid/liquid separation in various range of industries and applications includ: mineral concentrates, fine coals, effluent from mineral sands or aggregates wash plant, mud from industrial or mineral processes, thickening sludge from paste thickener or clarifier. Our filter presses are designed for bad environment such as mines or sludge treatment plants, which can 24-hour operation.

Dewatering Effects

More About Filter Press You May Consider?

Filter Press Used in Coal Mines

Filter Press Working Procedure

How Long A Filter Press Cycle Take

Download PDF: LZZG Filter Press

-

Working principle

How Does Filter Press Work?

Working Process: slurry is pumped into the filter press by high-pressure slurry pumps, the mixture flows through the filter medium (filter cloth), the solids stay on the filter cloths, forming filter cake; the filtrate exits the filter plates through the corner ports into the manifold, If it is not wanted the filtrate can be drained away for safe disposal.

Filter press is a pressure filtration method, which has the characteristics of fixed volume and batch operation, when the feed pumps generate pressure, solids build up in chambers until they are completely chock-full of. Once the chambers are full of solids, a fill cycle is over and the de-watered filter cakes will release, repeat the cycle, filter press will work cyclically.

-

Features & Benefits

- Filter presses are high strength, light weight, corrosion resistance, acid and alkali, non-toxic and tasteless.

- The frame rack is high strength, stable structure, long service life, small footprint.

- Automatic pull plate, liquid automatic access, operation panel is simple and safe, high degree of automation.

- Hydraulic system is used as the power unit, the maximum pressure is 25MPa.

- Provide suitable product for your specific application according the free field service.

- filter cake dryness, filtration cycle time, materials of components, number of chambers, filter plate size, filtration capacity is all stringently.

-

Specifications

Model Capacity (t/h) Filter Area (m²) Filter Plate (mm) Plate Number (block) Filter Pressure (mpa) Main Motor Power (kw) Weight (kg) Overall Size (mm) G60-100 1-1.5 60 1000X1000X65 37 0.6-0.8 3 4800 5120X1450X1360 G100-100 2-3 100 1000X1000X65 61 0.6-0.8 3 6630 6730X1450X1360 G150-125 3-5 150 1250X1250X65 57 0.6-0.8 4 7950 7560X1840X1620 G200-125 4-6 200 1250X1250X70 76 0.6-0.8 4 10800 9240X2050X1680 G250-125 5-7 250 1250X1250X70 94 0.6-0.8 6.25 12060 10580X2050X1680 G350-150 6-8 350 1500X1500X75 89 0.6-0.8 5.5 20880 10920X2500X1920 G400-150 9-11 400 1500X1500X75 102 0.6-0.8 5.5 23480 11930X2500X1920 G500-150 11-15 500 1500X1500X75 127 0.6-0.8 12.1 24880 13830X2500X1920 G800-200 20-25 800 2000X2000X83 113 0.6-0.8 12.5 48000 15100X3700X2400 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry