What is Frac Sand

Frac sand is a high-purity silica sand with very round grains, which is only distributed in a few places around the globe. Frac sand has super compressive property and extremely high roundness. Therefore, frac sand are usually used as as "proppants " pumped into the oil well with fracturing fluid , fills in the rock fracture, and forming a network of pore spaces that allow petroleum fluids to flow out of the rock and into the well.

Proppants used in the petroleum industry must meet very stringent specifications. The size, shape and mechanical strength of proppant will affect the integrity of fracture, thus affecting the outflow of oil and gas from the well.

CHAT NOW

Some Features that Made Frac Sand Popular

With the development of hydraulic fracturing technology in petroleum industry, the use of proppant began to increase sharply. Oil frac sand occupies a special place in the market for its superior features and low price advantage. High quality frac sand requires the following characteristics:

- High purity silica sand;

- Frac sand has sufficient compressive strength and wear resistance;

- The density of proppant is relatively low;

- Durability against the crushing force of closed cracks;

- Most frac sand used in the oil and gas industry is between 20-140 mesh.

How Frac Sand Is Processed

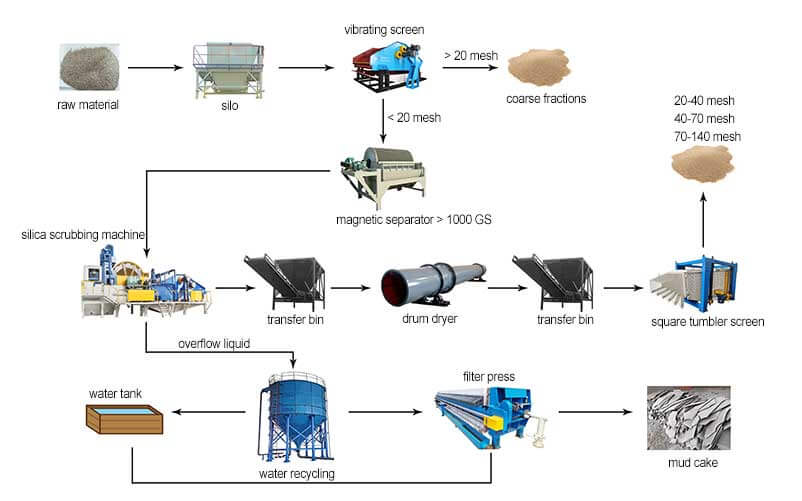

Natural frac sand is not used straight from the ground. After mining it is taken to a processing plant. There it is washed to remove fine particles and optimize its performance.

01Sizing

Frac sand raw materials are preliminarily screened by vibrating to screen off the unwanted coarse fractions(>20 mesh).

02Magnetic Separation

< 20 mesh frac sand is separated by magnetic separator to remove impurity iron.

03Scrubbing & Desliming

LZZG silica scrubbing machine removes the impurities wrapped on the silica sand surface through the attrition scrubber unit, and then removes the sludge and clay particles through the sand washing machine.

04Drying & Screening

Depositing the clean sand in to large rotating drums dryer fed by hot air, powered by either combustion or natural gas; Then making sharp separations with square tumbler vibrating screen; The product specifications can be controlled at 20, 4, 70 and 140 meshes as required.

05Effluent Recycling

The overflow water in the scrubbing and washing process can be recovered by the paste thickener, and generally 80-90% of the wastewater can be reused.

06Solids Management

Filter presses to process the mud from the underflow of the thickener into mud cakes that can be transported or stacked.

Popular Applications

With more than 30 years of sand washing industry experience, we have design and build over 20 frac sand plants for our customers. We provide all processes of the frac sand processing.

RelatedProducts

We will provide you with the most suitable products

Get InTouch

If you want to know the equipment information, or get the price,

please leave a message for us.