Overview

Attrition scrubbers are also called attrition cells, which are generally used before or after sand screws in sand washing plant to scrub the surfaces of particulates, break down impurities, and remove it from competent aggregate material to reduce the product turbidity.

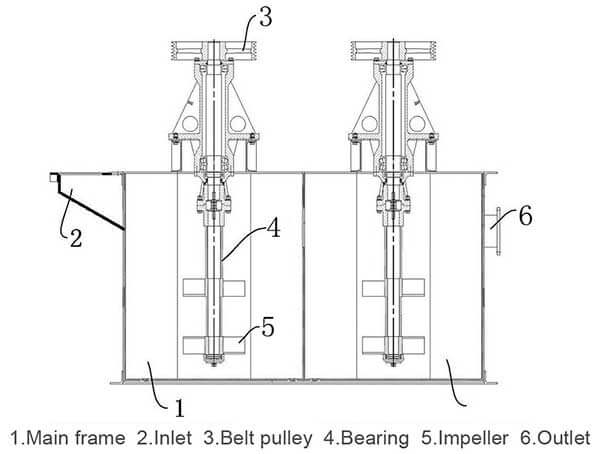

Attrition scrubber consists of a tank with a series of rotating paddles or blades that agitate the mineral particles and scrub them against each other, effectively removing any surface contaminants or coatings. The scrubbing action can also help to break down clay or other materials that might be clinging to the mineral particles. We design singl and multiple cell attrition scrubber units for different scrubbing requirements of mineral materials.

LZZG attrition scrubbers provide efficient scrubbing solutions for a variety of applications for sand, gravel, aggregate ore, coal and other industries.

-

Working principle

Slurry enters the scrubber cavity through the feed pipe, and produces severe turbulence under the strong agitation of impeller. The ore particles have great momentum in them and produce intense friction and collision with each other.

The impurity membrane wrapped on the surface of ore is easily peeled off the mineral surface by friction and impact due to its low strength. The cement surface is immersed in water and then the mineral particles are strongly rubbed and collided with each other to loosen and disintegrate, thereby achieving the separation of clay and ore.

These impurities and clay are disintegrated and exfoliated into the slurry, and the slurry can be separated by subsequent desliming. In the actual production process, different agents should be added according to the actual conditions of mineral.

-

Features & Benefits

- Large scrubbing intensity and good effect. The unique tank structure and impeller configuration increase the scrubbing strength by about 30% compared to the conventional scrubber of the same specification.

- Low power consumption, wear and corrosion resistance. The inner liner and impeller are made of wear-resistant materials.

- The light starting and small starting power greatly reduces the operator’s working intensity because of the impeller is above the pulp sedimentation zone.

- Simple structure, large effective volume, small floor space.

- Low circumferential speed and long service life.

- The relative position of ore feeding, ore discharge and the motor can be customized according to the needs of users.

Attrition scrubber structure:

Download: LZZG Attrition Scrubbers

-

Specifications

Model Feeding Size (mm) Capacity (t/h) Box Size (m³) Impeller Diameter (mm) Power (kw) Overall Size (mm) CX1-1 ≤10 10-30 1 480 15 1180*1150*2060 CX1-2 ≤10 10-30 1*2 480*2 30 2280*1150*2060 CX2-1 ≤10 20-50 2 520 30 1600*1600*2780 CX2-2 ≤10 20-50 2*2 520*2 60 3080*1600*2780 CX4-1 ≤10 40-80 4 770 55 1900*1760*3470 CX4-2 ≤10 40-80 4*2 770*2 110 3720*1760*3470 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry