Overview

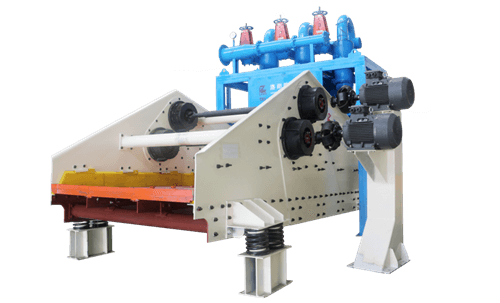

Tailings Dewatering Screen is the core equipment for mine tailings treatment. It achieves dry stacking of tailings through efficient dewatering, resolving the environmental and safety challenges of traditional wet discharge processes.

Core Components: Vibrator (adjustable amplitude), Rubber Spring Damping System (reduces energy consumption), Wear-Resistant Screen Panelsc.

LZZG Tailings Dewatering Screen employs dual-motor self-synchronizing drive technology. Two sets of eccentric blocks rotate in opposite directions to generate unidirectional excitation force, driving the screen box to vibrate linearly along a straight line. Installed at a negative inclination angle (typically 45°) and equipped with polyurethane elastic screen panels (open area ratio: 32%-42%), it accelerates material stratification and drainage. The moisture content of the screened product can be reduced to 15%-20%.LZZG tailings dewatering screen is suitable for iron/copper mines with high mud content, gold/silver mines with fine-grained tailings (-200 mesh accounting for ≤ 80%), as well as non-metallic tailings such as fluorite, barite, feldspar, quartz sand, etc

-

Working principle

Dry Discharge Process of Metal Tailings: Tailings slurry → Pre-concentration via hydrocyclone (underflow concentration ≥ 65%) → Dewatering by tailings dewatering screen → Conveyed to storage yard via belt conveyor.

This process can handle 70%-80% of tailings, significantly reducing the load on subsequent thickeners. Its comprehensive energy consumption is 15% lower than traditional filter press processes.

-

Features & Benefits

1. High efficiency, strong vibrating force and large capacity.

2. Simple structure and easy operation and maintenance.

3. 45°angle install increases the dewatering area.

4. Vibrating frequency is adjustable to meet different ores.

5. Torsional shear type high strength bolts are used between side plates and beam. No weld gap avoids side plates cracking during vibrating.

6. Polyurethane screen with better elasticity and less blocks. The PU side push plates protect the equipment from the rushing material and guard the long life of the whole device. -

Specifications

Model Capacity (t/h) Screen Panel (mm) Hydrocyclone (mm) Power (kw) Overall Size (mm) GP12-30 20-50 1200*2400 150*2 11 4280*2600*3000 GP15-60 60-100 1500*3000 150*4 22 4880*2900*3280 GP18-90 80-140 1800*4200 150*6 37 6080*3200*3500 GP24-120 120-200 2400*4800 150*8 44 6680*3800*3800 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry