Overview

LZZG deep cone thickener promoted the structure of internal feed tube on the basis of traditional vertical flow sedimentation tank,optimized flocculation and deep solids compression provide paste consistency underflow and higher process rates, which greatly increase settling efficiency.

The deep cone thickener is circular, suspended solids settle down into bottom conical sludge tank by gravity, clear water flow away from overflow port around the upper tank, which is also called paste thickener. The port of the overflow is equipped with filter and baffle, which improve the water quality that poured out.

Deep Cone Thickener Applications

Paste thickener in Vietnam

LZZG paste thickener in Korea

Sludge thickener in wastewater treatment

Related Categories

Sand & Gravel Washing Plant Design

Sand washing plant for tailing

Download thickener case: Applications of LZZG deep cone paste thickener in sludge treatment-

Working principle

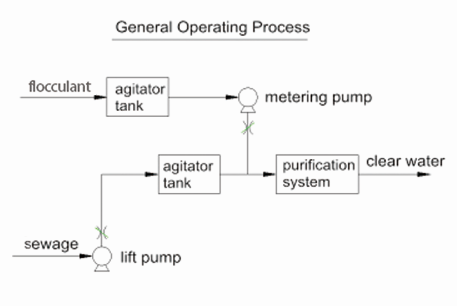

LZZG thickener is a thickener tank that based on gravity and sedimentation which makes solidseparate from liquid well. The concentration of pulp waste water could be enhanced from 2% ~ 15% to 60%~ 70% by the paste thickener, the clear water is overflow from the upper part of the paste thickener , so as to achieve the purpose of sewage purification, solid-liquid separation and maximum water recovery.

-

Features & Benefits

1.LZZG thickener automatic cleaning, automatic discharge slurry, solve manual operation;

2. Following the principle of suspension filtration, media adsorption and settling, maximum purification;

3. LZZG paste thickener use qualified carbon steel (or stainless steel), the machine has good strength and corrosion resistance;

4. Low flocculant using cost, big capacity, high efficiency, stable performance;

5. Small volume, small floor space, easy installation;

6. Service life is about 15 years, low investment but remarkable economic benefit;

7. The purified water by the paste thickener can totally reach to national standard of discharge and can be recycled;

8.LZZG can customize thickeners to suit the individual requirements. -

Specifications

Model Capacity (t/h) Tank Height (mm) Volume (m³) Weight (kg) Overall Size (mm) S-3045 <50 4000 35 5000 3600X3600X8860 S-3060 50-100 6000 50 6000 3600X3600X10860 S-6030 100-150 3000 100 12000 6600X6600X9400 S-6045 150-200 4000 130 15000 6600X6600X10400 S-6060 200-300 5000 160 17000 6600X6600X11400 S-8045 300-500 4500 300 23000 8000X8000X10800 S-8060 500-600 6000 330 28000 8000X8000X12300 S-1045 600-800 4500 500 42000 10000X10000X13000 S-1060 700-900 6000 600 48000 10000X10000X14500 S-1245 800-1000 4500 750 51000 12000X12000X13000 S-1260 1000-1200 6000 900 58000 12000X12000X14500 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry