Overview

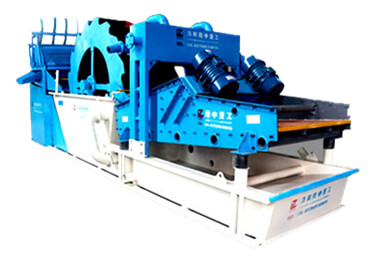

LZZG multi function modular washing plants are designed for maximum washing sand and recover the most part of the fine sand that mixed in water during the process.

Aggregates need to be cleaned in the drying treatment of sand washing plant, whether they are quarries or gravel, The most commonly washing case is artificial sand and natural sand. The use of hydrocyclone in modular washing plant is the most effective way to wash sand.

LZZG multi function modular sand washing plant equiped with hydrocyclones and could remove -63 micron material from the washed sand product. This effectively eliminating the loss of quality fines to waste water treatment phase, and the modular sand washing plants are widely used in mineral washing, recycling, rivers and lakes sand purification.

Related products:

-

Working principle

The quality sand after screening are fed into spiral washing tank through chute for primary washing, the spiral sitter tumbling and grinds to remove impurities covering the surface of sand.

The washed sand is taken away by the blades to feed into bucket sand washer. The muddy water and small specific gravity is taken away and pumped to desander cyclone for recycling, then also fed into bucket sand washer.

When the bucket moves, the sand is washed by bucket sand washer, then the clean sand fed onto polyurethane screen for dewatering. At the same time, muddy water and fine particles mixture is extracted to secondary desander cyclone for recycling fine sand, then also fed onto polyurethane screen for dewatering.

Then the finished product which is fully dehydrated by high frequency vibrating screen, will be transported into stock pile by belt conveyor.

-

Features & Benefits

1. Combine spiral sand washer, wheel sand washer in one for twice cleaning.

2. Efficient, energy saving, environmental protection.

3. Can be customized for different models, multi-layer screen.

4. Installation is simple, low maintenance costs.

5. Finished sand moisture content of less than 15%, mud content of less than 2%. -

Specifications

Model Feeding Size (mm) Capacity (t/h) Spiral Diameter (mm) Impeller Diameter (mm) Screen Panel (mm) Hydrocyclone(mm) Power (kw) Overall Size (mm) DS40 ≤10 20-40 760 1800X800 1200X2400 300X2 48.4 11900X5250X3880 DS60 ≤10 30-60 920 2600X1200 1500X3000 300X2 55 14550X5560X4150 DS80 ≤10 40-80 1120 3000X1600 1800X4200 300X4 95 16250X6200X3700 DS100 ≤10 60-100 920X2 3000X1600 1800X4200 300X4 110.5 16250X6200X3700 DS150 ≤10 100-150 1120X2 3600X2000 2400X4200 350X4 140.5 17450X6800X3700 DS160 ≤10 100-160 1120X2 3600X2400 3000X4800 300X6 168 18000X7400X4260 DS200 ≤10 120-200 1500X2 3600X2400 3000X4800 350X6 196 18000X7400X4600 DS250 ≤10 160-250 1500X2 4200X3000 3600X6000 350X6 214 18580X8000X5200 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Sand washing and dewatering machine

Sand washing and dewatering machine Sand washing and recycling machine<

Sand washing and recycling machine< Trommel type sand washer

Trommel type sand washer Spiral sand washing and recycling machine

Spiral sand washing and recycling machine

Inquiry