Overview

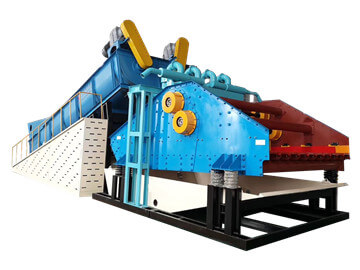

The spiral sand washer is a high efficient and multi-functional water washing equipment, which is composed of a spiral sand washing machine and a dewatering screen and hydrocyclones. Compared to the purchase price of equipment alone, the choice of spiral sand washing machine is undoubtedly more cost-effective.

The spiral sand washing machine consists of spiral sand washing device, overflow device, water reverse device, separation and recovery device, water storage tank, slurry pump, elrctro motor, reducer and so on.

-

Working principle

When the washing system is working, the crushing and grading materials are firstly sent to the spiral washing device by belt conveyor, after grading and washing, the qualified material is sent into the dewatering unit, and the remaining waste water that after washing by the spiral sand washing device (containing a part of qualified material) is overflowing from the weir and get into water tank.

The overflowed mud water is pumped into hydrocyclones by slurry pump, and the fine materials in mud are concentrated under the action of centrifugal force. Finally, the concentrated fine materials are sprayed on the dewatering unit and dewatering together with qualified materials.

-

Features & Benefits

-

Specifications

Model Feeding Size (mm) Capacity (t/h) Spiral Diameter (mm) Hydrocyclone (mm) Screen Panel(mm) Power (kw) Overall Size (mm) LY40 ≤10 20-40 760 250X2 1200X2400 37.4 10880X5240X3720 LY60 ≤10 30-60 920 300X2 1500X3000 51 11490X5560X3960 LY80 ≤10 40-80 1120 300X2 1800X4200 59.5 12830X5860X4250 2LY100 ≤10 60-100 920X2 350X2 1800X4200 82 12630X5850X3860 2LY150 ≤10 100-150 1120X2 300X4 2400X4200 97 12630X6450X4150 2LY160 ≤10 100-160 1120X2 350X4 3000X4800 141 13560X7860X4300 2LY200 ≤10 100-160 1120X2 350X4 3000X6000 148 14760X7860X4300 2LY250 ≤10 160-250 1500X2 300X6 3600X6000 178 14760X7920X4900 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry