The Structure And Working Principle Of Hydraulic Classifier

LSF Hydraulic Classifier is mainly designed for the screening and recovery of fine-grained sand and gravel. It can be used in mining, aggregate processing, piling mud, river dredging, coal slime separation, photovoltaic quartz sand raw material production and processing, ceramic raw material processing, silica sand processing, fracturing sand processing, and various metal tailings treatments.

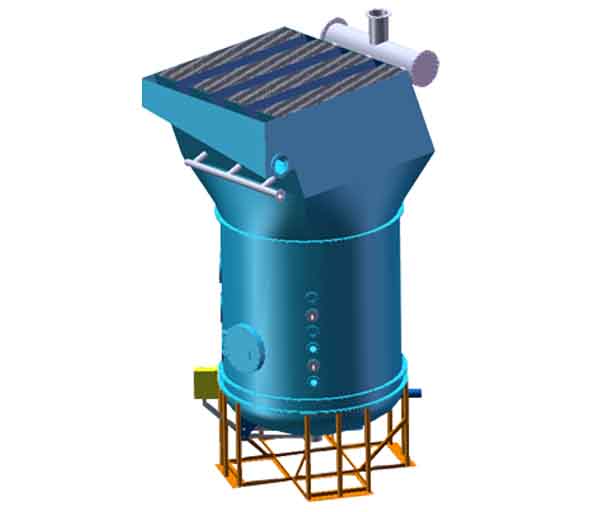

The structure of hydraulic classifier

The basic structure of the hydraulic classifier is circular, and the main body is composed of an upper cylinder and a lower cone. Efficient classification is accomplished using fluidized bed and rising water technology in the middle coarse-grained classification chamber and the surrounding annular fine-grained classification chamber.

The working principle of hydraulic classifier

Hydraulic classification is to divide the mixed particle groups with a wide particle size range into several particle groups with a narrow particle size range according to the difference in sedimentation velocity of mineral particles in water. The classification process is based on their different movement speeds in the water. At this time, large and light mineral particles and small and heavy mineral particles have the same settling speed, thus forming a particle size class. Therefore, hydraulic classification is performed not only by particle size, but also by specific gravity. The equipment used for grading is called a classifier. The commonly used hydraulic classifier is a box-type hydraulic multi-chamber classifier. This classifier is also called a mechanical ore discharge trough classifier. This kind of classifier is commonly used in tungsten ore beneficiation plants as a shaker to classify materials before sorting. Its suitable classification particle size range is 2-3 mm, but the classification effect is poor for particles smaller than 0.074 mm.

What are ultrafine materials?

Ultrafine materials are materials with special functions that are necessary in many fields such as fine ceramics, electronic components, bioengineering processes, new printing materials, high-quality refractory materials, and materials related to fine chemicals.

The necessity of grading ultrafine materials

In the process of preparing ultrafine materials, the products must be classified. On the one hand, the product particle size is controlled to be within the required distribution range, and on the other hand, the products that have reached the required particle size in the mixed materials are separated in time, and the coarse particles are returned for re-crushing, so as to improve the crushing efficiency and reduce energy consumption.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.