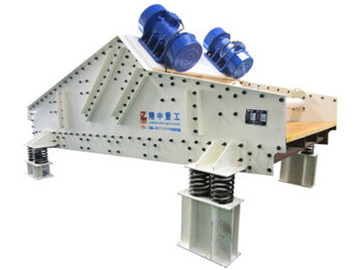

Coal Vibrating Screen in Sri Lanka

The basic working part of coal washing and screening equipment is the screen surface, on which there are screen holes of a certain shape and size. Generally, two products can be obtained on one screen surface. The material remaining on the screen surface is called the oversieve, and the material passing through the screen is called the underscreen. Screening on several sieve surfaces with different sieve openings in sequence can obtain products of different particle size levels.

The operation of dividing the mixed materials of different particle sizes into various particle sizes with a perforated screen is called sieving. The machine or device used for screening is called vibrating screen.

Types of coal vibrating screen operations

1. Pre-screening

In the coal preparation plant, according to the requirements of the crushing operation and the sorting operation, the raw coal is divided into different sizes to prepare for the further work of the coal. For the sorting operation, due to various coal preparation methods, a certain selected particle size is required, otherwise the sorting effect will be seriously affected, so the raw coal should be divided into different particle sizes as required.

2. Dewatering screening

Sieving for the purpose of dehydration. In the coal preparation plant, the screen used for the dehydration of the processed products is called the dehydration screen.

3. Desliming and screening

Screening for the purpose of removing slime. In order to reduce the pollution of high-ash fine sludge to the clean coal, the coal preparation plant strengthens water jet washing to remove part of the fine sludge during the dehydration process on the screen. This operation is called desliming and screening. In a heavy-medium coal preparation plant, in order to reduce the pollution of coal slime to the media system, desliming and screening are also used before the coal enters the heavy-medium separator.

4. Removal of heavy media

In the heavy-medium coal preparation plant, the product of heavy-medium coal preparation is sprayed with strong clean water on the screen to separate the product from the heavier quality. This kind of job is called off-media job.

5. Slime recovery

Screening for the purpose of recovering slime is used for dewatering of slime and tailings in coal preparation plants.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.