Overview

Crawler Type Wash Plant is a track-mounted mobile sand and gravel washing machine, which is widely used for washing and classifying in many industries, sand and gravel production plants, mines, building materials factories, transportation, chemical industry, water conservancy and hydropower, and concrete mixing.

Through the crawler, the mobile operation of the washing is realized, and the operation mode is more flexible. It is powered by diesel and electricity, either external power supply or diesel only. The sand washing effect is good by twice washing, it can deal with those sand with higher mud content. Besides, it can recycle waste water to high resource utilization rate. It can be equipped with satellite positioning and lock function, supporting various forms of commercial sales and cooperation. This mobile plant owns advanced technology, intelligent monitoring and control system, has wireless remote monitoring, data transmission, data analysis and remote control functions.

-

Working principle

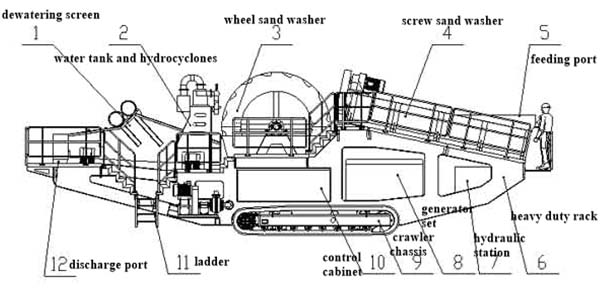

Structures: mainly composed of power system, walking system, hydraulic drive and steering system, working system, control system, etc.

Main components: crawler device, hydraulic motor and planetary reducer, generator set (including engine and generator), hydraulic workstation, control cabinet, frame, working device (spiral sand washing + wheel sand washing + dewatering screen), working platform, remote control device, and optional satellite positioning mechanism, information monitoring and information transmission system, etc.

Working process: the quality sand after screening are fed into spiral washing tank through chute for primary washing, the spiral sitter tumbling and grinds to remove impurities covering the surface of sand.

The washed sand is taken away by the blades to feed into bucket sand washer. The muddy water and small specific gravity is taken away and pumped to desander cyclone for recycling, then also fed into bucket sand washer.

When the bucket moves, the sand is washed by bucket sand washer, then the clean sand fed onto polyurethane screen for dewatering. At the same time, muddy water and fine particles mixture is extracted to secondary desander cyclone for recycling fine sand, then also fed onto polyurethane screen for dewatering.

Then the finished product which is fully dehydrated by high frequency vibrating screen, will be transported into stock pile by belt conveyor.

-

Features & Benefits

1. Dual power by diesel and electricity. When electricity is available, it can work by electricity. When there is no electricity, it can work by diesel generating set.

2. High mobility, more flexibleoperation. Compared with the traditional wheeled mobile sand washing station, it can walk, reverse, turn, climb without traction.

3. High Can be freely combined with various belt conveyors and production lines.

4. Simple operation. Crawler walking can be realized by a handheld remote control.

5. Advanced technology and stable performance. The electronic control system has the function of interlocking function, button operation, PLC touch screen control, and fault diagnosis. The electro-hydraulic proportional control technology is used for walking, frequency conversion start, soft start and stop, adjustable deviation, reasonable kinetic energy structure matching, and more energy saving.

6. Electro-hydraulic dual-power interfaceis provided, which can help to finish peripheral work such as feeding material transportation, discharge transportation, lighting, and oil cylinders.

7. It has remote positioning and lock function, which has accurate positioning, reliable lock and high safety factor.

8. It hasvideo monitoring, signal transmission, wireless remote control and other functions, and can also perform data analysis and fault analysis through data recording.

9. All machine are driven by a motor as standard, and can also be driven by a hydraulic motor.

10. The machine can be customized by customers’requirements.

-

Specifications

Model Spiral Size (mm) Impeller Size (mm) Screen Panel (mm) Power (kw) Overall Size (mm) LD80 2LX760 XSD2512 TS1530 75 12500*3000*4500 LD100 2LX920 XSD3016 TS1842 110 14430*3500*4500 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry