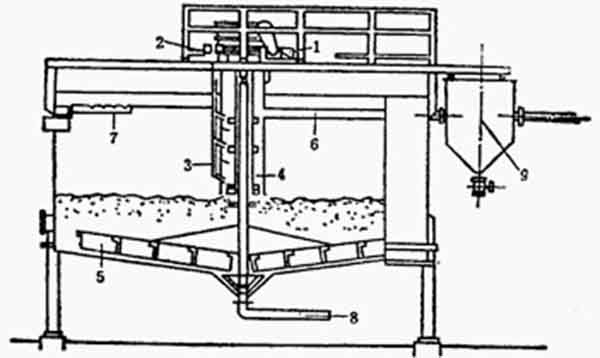

High Efficiency Thickener Components

High efficiency thickener is mainly used for solid-liquid separation processes such as liquid concentration and wastewater treatment. The increased height-to-diameter ratio of the high-efficiency thickener allows the fine-grained pulp to stay longer in the machine. The application of high-molecular flocculant strengthens the coagulation effect of the pulp, thereby producing clearer overflow water and thicker underflow.

High efficiency thickener structure

The transmission structure of the tank and rake frame of the high-efficiency thickener is roughly the same as that of the ordinary thickener. The high concentration efficiency is mainly due to the special feeding barrel. There are three main types of high-efficiency thickeners commonly used abroad: Einco-BSP type, Dorr-Oliver type, Enviro-Cldar type. The feeding drum is divided into three vertical mechanical mixing chambers, which are concentric with the central vertical axis of the thickener. The ore slurry enters the mixing chamber through the feeding pipe, and after being fully mixed with the flocculant, it is directly fed to the middle and upper part of the sedimentation layer through the feeding pipe radially distributed in the lower part of the mixing chamber. After the liquid is filtered by the sand layer, it rises to overflow, and the flocs stay in the sand layer and enter the underflow.

High efficiency thickener components

1. Rake drive device

2. Mixer transmission

3. Flocculant feed pipe

4. Feeding barrel

5. Rake arm

6. Feeding barrel

7. Overflow trough

8. Discharge tube

9. Exhaust system

High efficiency thickener working principle

Increasing the size of the solid particles in the slurry and the settlement area of the thickener can improve the processing capacity of the thickener. Add flocculant to the thickener to agglomerate the fine particles into agglomerates, which can increase the size of the settled particles. Putting the inclined plate in the ordinary thickener can increase the sedimentation area, shorten the sedimentation distance of the particles, and improve the concentration efficiency. The test production shows that under the same processing capacity, the diameter of the high-efficiency thickener is only two-thirds to one-half of the diameter of the ordinary thickener, and the area is about one-ninth to one-fourth of the ordinary thickener. However, the processing capacity per unit area can be increased several times to several tens of times.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.