Overview

LZZG Ultra Fine Sand Recovery Unit uses hydrocyclone recover fine sand that overflowing from the sand washing plants, generally, 0.04-3mm fine materials can be well recycled >95%, without additional chemicals.

LZZG Ultra Fine Sand Recovery Unit is designed 30-350tph and produced final product with residual water content 10–15%. This recycling units are suitable for aggregates, coal ,concrete, frac sand, idustrial sands, frac sand, and more.

-

Working principle

The overflow of washing machines(wheel washers or washer screws)is fed to hydrocyclones by slurry pump with high pressure. Most fine materials (+300 mesh) concentrated by hydrocyclones goes to dewatering screen through underflow exit. After dewatering, the hydrocyclone underflow turn to be a dryer materials, moisture content <20%.

Little fine materials and mud passing through the dewatering screen panels goes back to water tank, with pump and hydrocyclones, fines recycling preocess will recirculated. The fines fineness can be regulated by hydrocyclone sizes, water volume and pump speed.

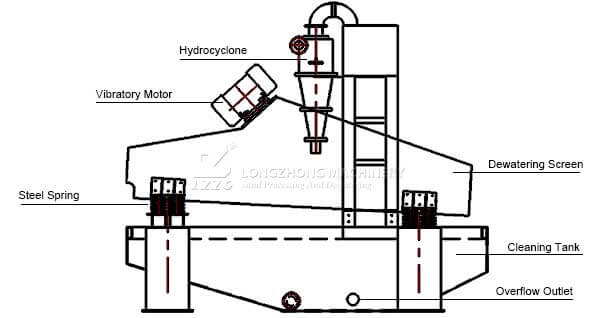

LZZG recovery unit is consist of Hydrocyclones, Vibratory Motor, Dewatering Screen, Cleaning Tank, Overflow Outlet, Steel Spring, Pump etc.

-

Features & Benefits

1.Fine sand recovery system can recover 85% of the whole fine particle.

2.Maximum fines recovery, 0.04-3mm is available, lower mud content.

3.Compact structure and install easily.

4.Final water content can be reduced to 10-15%.

5.Customized sand recycling equipments are supportive.

-

Specifications

Model Feeding Size (mm) Capacity (t/h) Screen Panel (mm) Hydrocyclone (mm) Power (kw) Overall Size (mm) LZ1530-65 ≤10 30-60 1500X3000 300X2 36 3300X5250X3000 LZ1842-75 ≤10 40-80 1800X4200 350X2 48 4600X5560X3520 LZ1842J-100 ≤10 60-100 1800X4200 250X4 59 4600X5560X3520 LZ2442J-120 ≤10 100-150 2400X4200 300X4 82 4600X6250X3600 LZ3442J-140 ≤10 100-150 2400X4800 350X4 96 4600X6250X3600 LZ3048J-140 ≤10 120-200 3000X4800 350X4 104 5400X7000X4200 LZ3060J-180 ≤10 120-200 3000X6000 300X6 127 6600X7000X4200 LZ3660J-180 ≤10 150-250 3600X6000 300X6 134 6600X7000X4800 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry