Overview

LZZG Vortex Sand Washer combines cyclones and dewatering screen. When it comes to application, the cyclone remove clays, silts and slime from sand and bring it into demands, the dewatering screen enables low moisture product for conveying or stockpiling.

LZZG Vortex Sand Washer has an optimised process that produces a drier, higher-quality product with less fines. They can also be used to wash a range of feed materials such as:

- Concrete

- Gravel

- Frac Sand

- Silica Sand

- Mineral Sands

- Oil Sands

- Bauxite / Alumina

- Slag

-

Working principle

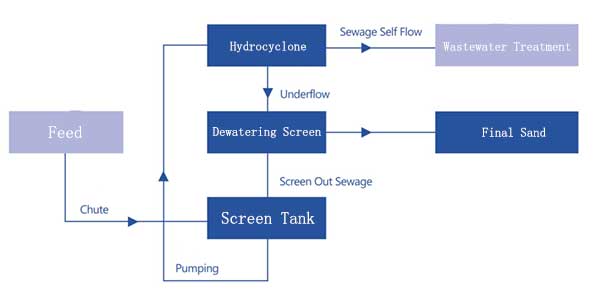

The mixed material enters the screen underflow tank through a chute, and then is pumped into the cyclone. Under the action of centrifugal force, the material is cleaned and dewatered to achieve mud-sand separation.

The underflow material of the cyclone enters the coarse sand dewatering zone of the linear screen for dewatering; while the overflow material enters the water tank through the return pipe for circulating cleaning and replenishing of the water tank, thus achieving efficient sand washing.

-

Features & Benefits

Built-in float system that effectively controls the liquid level.

Large channel slurry pump with rubber lined, increases the operational life.

Grille walkway steps, fully integrated guardrail.

Custom cyclone options for enhanced recovery.

Replaceable independent elbows with ceramic wear-resistant linings.

Inlet buffer tank reduces turbulence to ensure consistent and uniform flow.

-

Specifications

Model Capacity (t/h) Dewatering Unit Cyclone Unit Power (kw) Overall Size (mm) LZS660 80-100 TS1536 FX660 43.4 7690*3915*6695 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry