Overview

Gravity thickener is a solid-liquid separation equipment based on gravity settlement, which is similar to clarifier and sedimentation tank. It can make suspended solids in the slurry gradually sink to the bottom of the tank.

Gravity thickeners are often used in mining, metallurgy and other industries to process various minerals, metals and non-metals. In addition, gravity thickeners can also be used in industrial wastewater treatment, environmental protection governance and other fields.

-

Working principle

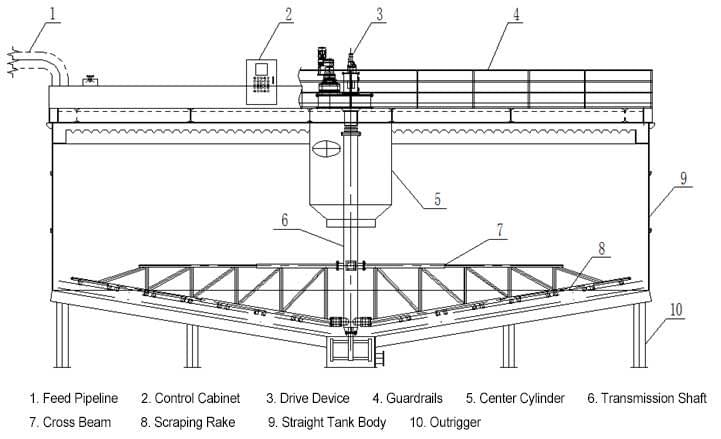

When working, the slurry is mixed with the flocculant and enters the gravity thickener through the central cylinder. The slurry is guided from the feed vertical cylinder to the surrounding areas by the guide plate at the outlet of the feed vertical cylinder, allowing the slurry to diffuse to the surrounding areas.

A gravity thickener can concentrate slurry with a solid content of 10% -20% into underflow slurry with a solid content of 45% -55% through gravity settling. With the help of a rake installed in the thickener, the thickened underflow slurry is discharged from the underflow port of the thickener. The upper layer of clear water is discharged from the top drainage outlet to achieve mud water separation.

-

Features & Benefits

1. Large processing capacity per unit volume and high concentration efficiency.

2. Hydraulic multi-point drive, infinite speed regulation, high mechanical strength, with overload protection function.

3. The hydraulic rake lifting device is used for reliable operation.

-

Specifications

Model Diameter (m) Settlement Area (m²) Taper (°) Power (kw) Overall Size (m) NMJ10 10 78 10 11 φ10*7.9 NMJ12 12 113 10 11 φ12*8.1 NMJ14 14 153 10 11 φ14*8.3 NMJ16 16 200 10 11 φ16*8.5 NMJ18 18 254 10 11 φ18*8.7 NMJ20 20 314 10 11 φ20*8.9 NMJ22 22 380 10 16.5 φ22*9.1 NMJ24 24 450 10 16.5 φ24*9.2 NMJ26 26 530 10 16.5 φ26*9.6 NMJ28 28 615 10 22 φ28*9.8 NMJ30 30 708 10 22 φ30*10 -

Inquiry

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.

Inquiry