What Is The Hydraulic Classifier Method?

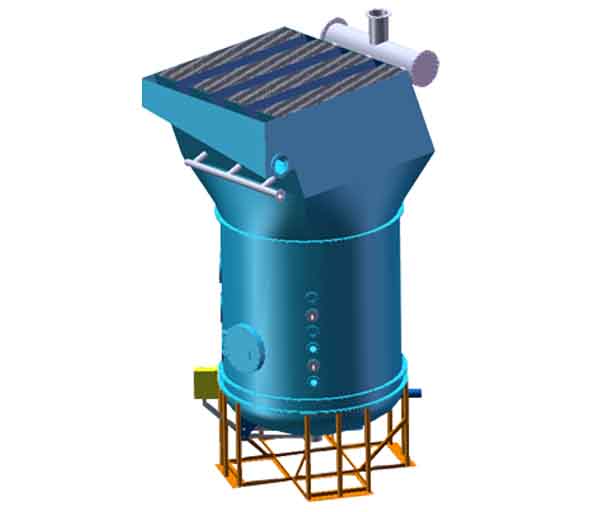

The hydraulic classifier is mainly used for the separation of tin, lead, and zinc, as well as classification and selection of glass sand, to eliminate coarse particles and heavy minerals in sand and recover qualified foundry sand. The hydraulic classifier uses rising water to create turbulent flow in the container, causing large particles or particles with higher specific gravity to concentrate at the bottom of the container and be discharged from the bottom valve. Smaller particles and particles with lower specific gravity overflow from the overflow weir and collect in the overflow tank, thus achieving the separation of various minerals.

What is the hydraulic classifier method?

A hydraulic classifier is an obstructed sedimentation machine that uses an ascending water flow to create turbulent flow within a container. Rising water enters the water tank at a predetermined flow rate and pressure, and material is fed into the equipment via a feeder. Larger particles of the same specific gravity settle faster than smaller particles. For particles of the same size but different specific gravities, the heavier particles settle faster than the lighter ones. Within a certain range of particle sizes, the ascending water flow keeps particles in suspension; this area is called the turbulent zone. Larger particles or those with higher specific gravity in the incoming material pass through the turbulent zone and settle. Smaller particles or those with lower specific gravity do not pass through the turbulent zone and float upwards. The material overflows the overflow weir and collects in the overflow trough. A pressure gauge is inserted into the slurry in the turbulent zone, indicating the slurry pressure. The material is continuously sorted according to this process.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.