Pure Silica Sand Processing Plant And Techniques/Frac Sand

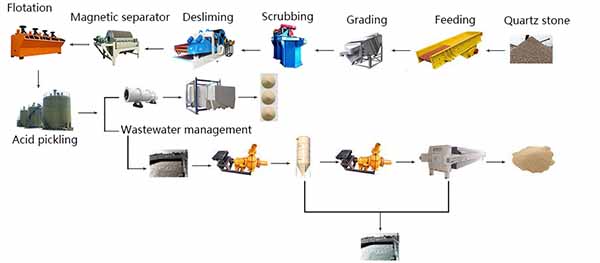

Pure silica sand processing techniques is a purification technology, which is mainly to remove small or trace impurities in the silica sand to obtain refined silica sand or high purity silica sand. The purification processes of silica sand at home and abroad mainly include grading, desliming, scrubbing, magnetic separation, flotation, acid pickling, etc.

Pure silica sand processing techniques

1. Grading

The linear vibrating screen is generally used to complete the grading process, which is mainly to screen out qualified sand. The finely crushed silica enters the vibrating screen for grading. Silica sand that meets the particle size requirements will enter the subsequent link, and the quartz sand that fails to meet the standard will be returned to the crushing link and crushed again.

2. Scrubbing

Scrubbing is to remove the thin film iron and muddy impurities on the surface of silica sand by mechanical force and the abrasive force between the sand grains and to further grind the unconsolidated mineral aggregates. At present, there are mainly two methods of rod scrubbing and mechanical scrubbing.

3. Desliming

The quality of SiO2 in quartz sand decreases with the fineness of quartz sand, but the quality of impurity minerals is the opposite. Especially obvious in quartz sand containing a lot of clay minerals. Therefore, it is very necessary to wash and deslime the quartz sand ore before being selected.

4. Magnetic separation

In general, the common impurity minerals of silica sand such as limonite, tourmaline, hematite, and biotite can be removed only by the magnetic separation process. In actual production, the wet strong magnetic separator is often used for selection, and the magnetic field strength is about 13000 Oersted.

5. Flotation

The separation of mica and quartz is difficult. Using anionic collector under acidic conditions, or anion-cation collector under alkaline conditions, flotation can obtain good results. Generally, after scrubbing, desilting, magnetic separation, and flotation, the purity of silica sand can reach more than 99%, which basically meets the needs of industrial sand.

6. Acid pickling

Dilute acid has a significant effect on the removal of iron and aluminum, while the removal of titanium and chromium uses concentrated sulfuric acid. Generally, the mixed acid composed of the above acids is used for acid leaching and removal of impurity minerals. The degree of acid leaching should be based on the final quality requirements of silica sand. Try to reduce the acid concentration, temperature, and dosage to achieve silica purification at a lower beneficiation cost.

7. Wastewater management

LZZG wastewater treatment system(thickener+filter press) for process and recovery above 90% water.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.