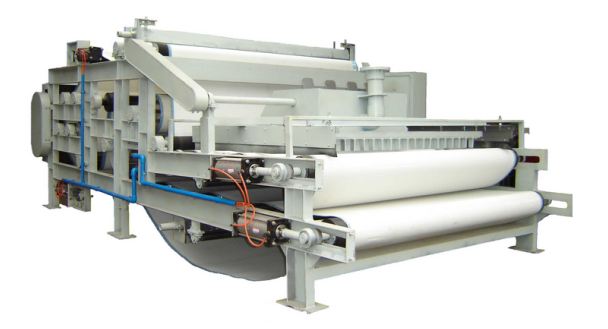

Belt filter press for sludge dewatering

Belt filter press for sludge dewatering as an important part of sludge treatment, which mainly by large gravity drainage and wedge sections for maximum free water drainage. Because of the large volume and in liquid flow, sludge must be dewatered to reduce sludge volume and facilitate transportation.

Sludge dewatering belt press generally consists of filter belt, roller cylinder, filter belt tensioning system, filter belt deflection system, filter belt washing system and filter belt drive system. Belt press filter dewatering machines come in many forms, but are generally divided into four working areas: gravity dewatering zone, wedge dewatering zone, low pressure dewatering zone and high pressure dewatering zone.

How it works?

1. The flocculated sludge first enters the gravity dewatering zone, and most of the free water is filtered by filter belt under the action of gravity.

2. As the filter belt runs, sludge enters a wedge-shaped zone composed of two filter belts and slowly pressurized by two filter belts, so the sludge gradually thickens and fluidity decreases, and the transition to the pressing zone.

3. In the pressurizing zone, the sludge is subjected to the increasing pressing force and the shearing force generated by the alternating upper and lower positions of two filter belts. Most of the free water and interstitial water remaining in the sludge are filtered out, and the sludge becomes a flake cake with a lower moisture content.

4. The upper and lower filter belts are separated by the unloading roller, and the filter cake is scraped off by the change of the curvature of the filter belt to achieve solid-liquid separation of the material, and the upper and lower filter belts are reused after being washed, and the concentrated pressure of the next cycle is performed. filter.

Routine maintenance

1. The sludge dewatering belt filter press should wash the filter belt before opening and after stopping, so as to prevent the sludge from shrinking on the machine and affect the use of filter belt. When cleaning, to avoid water to electrical parts to avoid electric shock.

2. Discharge the condensate in compressor at least once per shift, and often open the pneumatic bottom valve to drain the condensate from the air line.

3. Always check the oil cup of the air compressor and the oil cup on the gearbox. If the oil level is too low, the oil should be replenished. For slow rotation shafts such as roller cylinders and rollers, grease should be added regularly to prevent corrosion due to water ingress, dry grinding, etc.

4. In order to operate safely, remember to connect the neutral or ground wire to ensure protection when the device leaks.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.