What is dewatering screen with cyclone?

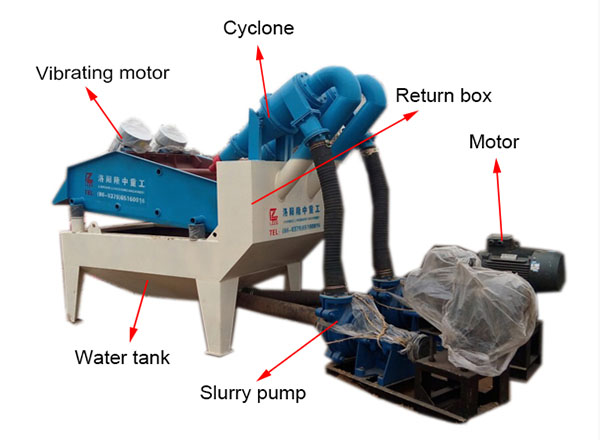

Dewatering screen with cyclone is a common equipment in mine industry, which can be widely used in mine, ores, slurry, sand washing plant, sand production plant, quarry, construction, concrete mixing plant, etc. At LZZG, we also called dewatering screen with cyclone as a sand recycling machine.

The material as following is mainly introduced as fine sand.

What is dewatering screen with cyclone?

Sand washing machine is a indispensable equipment in sand and gravel processing plant. But you should all know the sand washing machinery has a big drawbacks, which is the serious fine material loss.

Dewatering screen with cyclone is designed to solve the above problem that sand washing machine left, which is as the name implies, is a equipment that mainly composed of vibrating dewatering screen and cyclone. So we also called it fine sand recycling machine. It is mainly for recycling 0.074-3mm(250mesh-100mesh) fine sand, so the loss amount of fine sand can be controlled within 5%, which can solve the high fineness of finished sand fineness and the partiality of stone powder in the artificial aggregate processing system.

How does it work?

Through rubber pipes sand and water mixture is extracted from cleaning tank into slurry pump. The fine sand is collected by the centrifugal force of cyclone, then fed to the polyurethane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen. The waste water will flow back to the return box, through weld chute or pipes flowing to a settling pond.

Features:

1. Recycling 0.074-3mm fine sand.

2. Recycling rate reaches above 95%.

3. The water content of final sand is within 12%-15%.

4. Effectively reduce the loss of fine sand, solve the problem of sedimentation tank accumulates.

Some factors that affect the recycling effect

1. Concentration of solids

The recovery of dewatering screen with cyclone is premised on the muddy water formation by sand and water mixing in a certain proportion. When the muddy water is too dense of feeding into dewatering screen with cyclone machine, it will damage the slurry pump to a certain extent. And affecting the recovery efficiency of fine sand recovery machine. Therefore, a reasonable proportion of muddy water mixture is one if a foremost factors that affect the recovery effect of dewatering screen with cyclone machine. The most suitable concentration that feed into our dewatering screen with cyclone machine is less than 30%.

2. Sand properties

The composition and physical properties of sand have a great influence on fine sand recycling rate of fine sand recovery machine. For example, when the useful sand is coarse in grain size and the structure is loose and brittle, it is easier to grind. When the useful sand have a finer grain size, a finer structure, and a higher hardness, it is more difficult to recycle. In general, the coarse-grained grade is relatively simple in rough grinding, the rate of passing the qualified grain is faster, and the fine grinding is more difficult.

3. Operational factors

The operational factors will undoubtedly affect the recycling rate of fine sand recycling machine. For example, in the case of closed-loop sand processing plant, when the sand-return rate is too large and exceeds the normal passing capacity of fine sand recovery machine, the“running rough”scene will appear in the products. The return sand ratio is too small, or there is no sand return, it is easy to form a destruction scene. If the load is too large, the “running rough” scene in the products is severe. And the load is insufficient, damage is severe. Therefore, the fine sand is required to be even and stable. When the amount of sand is given, the efficiency of fine sand recovery machine will be increased.

4. Screen opening rate

The larger opening rate on sieve surface, the better pass performance. In the case of ensuring the strength of screen surface, the imported polyurethane screen can obtain a higher opening ratio than the common screen, and thus the pass performance of the former is superior to the latter. The mesh and its wire diameter have certain influences, generally with a difference of about 5%.

5. The thickness of material accumulation on sieve plate

When using a flat screen, if the material layer passing through the sieve surface is too thick, it is difficult for the small particles in the upper part to pass through the sieve hole. This will increase the net material loss in the raw material cleaning, and reduce the yield in the sand particle grading and affect the quality of finished product. If the layer is too thin, the recovery yield is too low and it is not desirable. The thickness of a suitable layer should be determined by experiment. When the angle of screen is small and the amplitude of is large, the layer can be slightly thicker. In theory, the thickness of layer is determined by the yield. But in actual use, due to the uneven feeding of screen surface, the material may be concentrated on one side of the screen surface. To causing the local layer to be too thick and affect the recovery effect. Cylindrical sieves and conical sieves have similar problems. When the instantaneous material flow rate is too large, the recovery effect is also affected, but in large gravel equipment, the two equipment are used less.

The dewatering screen with cyclone will be your best choice if you have fine material is needed to recycle and dewater.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.