100T/H Silica Sand Mining Processing Plant

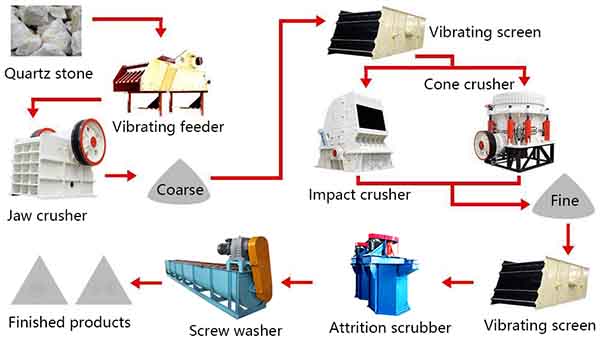

The process of silica sand mining processing plant is roughly divided into crushing, grading, scrubbing, desilting, and magnetic separation to maximize the purity of quartz sand. Due to the mature processing technology of the silica sand processing plant, the quality of finished products is also high.

The basic silica sand making process and dust removal and impurity removal functions. For the high pure requirements of silica sand, high-purity extraction such as flotation, magnetic separation, and spot selection is also required.

Silica sand processing plant and equipment

According to the production process, the equipment used in silica sand processing generally involves four major parts: crushing, sand making, screening, and sand washing.

1. Crushing

Crushing is divided into one crushing molding and two crushing moldings. Like the hammer crusher can achieve a molding, no need for secondary crushing. But relatively low output, suitable for small silica sand processing plants. Large-scale quartz sand processing plant is suitable for jaw crusher + cone crusher, the effect will be better.

2. Grading

The circular vibrating screen is generally used to complete the grading process, which is mainly to screen out qualified sand. The finely crushed silica enters the vibrating screen for grading. Silica sand that meets the particle size requirements will enter the subsequent link, and the quartz sand that fails to meet the standard will be returned to the crushing link and crushed again.

3. Scrubbing

Scrubbing is to remove the thin film iron and muddy impurities on the surface of silica sand by mechanical force and the abrasive force between the sand grains and to further grind the unconsolidated mineral aggregates. At present, there are mainly two methods of rod scrubbing and mechanical scrubbing.

4. Washing and desliming

Washing and desliming part plays a basic role in purifying and impurities removing by cleaning the silica sand. Available in wheeled and spiral models.

5. Magnetic separation

In general, the common impurity minerals of silica sand such as limonite, tourmaline, hematite, and biotite can be removed only by the magnetic separation process. In actual production, the wet strong magnetic separator is often used for selection, and the magnetic field strength is about 13000 Oersted.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.