Filter Press Manufacturer

As a solid-liquid separation equipment, the filter press has a long history in the application of materials dewatering and liquids solids separation. Specifically, the slurry is pumped into the filter press chambers. Under the action of the pressure pump, the filter plates extrude each other, so the low moisture content cake is formed and released.

LZZG customized filter presses feature good separation effect and wide adaptability, especially for the sticky and fine materials. Whether you require a high capacity of Filter Press or a smaller footprint design, we will design best option standard or specific filter press solutions for each user based on the volume and type of slurry that needs to be dewatered.

As a professional filter press manufacturer, LZZG's extensive range of industrial filter presses, including plate filter press, belt filter press as well as a range of optional equipment accessories: automatic filter cloth cleaning system, auto plate shifting device, auto plate shaking device, automatic hydraulic device, and PLC auto-control, etc.

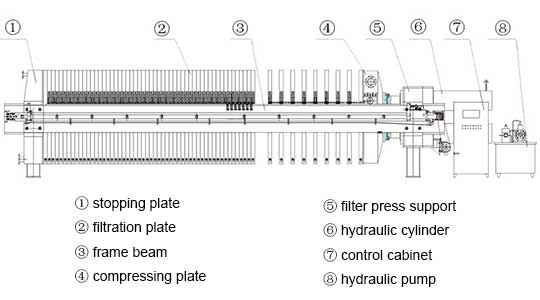

How Plate Filter Press Work

The plate filter press is mainly composed of frame, filter plates, piping, valves, and filter cloth. When working, the slurry is fed into filter chambers by slurry pump, slurry solids will be trapped in chambers and formed into solids cake, while the clean filtrate liquid passes through the filter cloth and exits via the filter plates grid.

When chambers are full of solids, the feed is stopped, hydraulic pressure releases and mud cake fall. Repeat the filter press cycle and the filter press will continue to work. The fill cycle is mainly dependent on the nature of material to be dewatered, the concentration of the solids in the slurry, the feed pressure and filter cloth types. But the automatic plate shifting devices will speeding cycle time greatly.

Befefits & Features

Automatic plate shakers ensure complete cake discharge.

automatic filter cloth cleaning system.

Suitable for various scenes of small and medium sludge dewatering treatment.

Flexible selection of filter area:1m2 to 500m2.

Specifications

| Model | Capacity (t/h) | Filter Area (m²) | Filter Plate (mm) | Plate Number (block) | Filter Pressure (mpa) | Overall Size (mm) |

| G100-100 | 2-3 | 100 | 1000*1000*60 | 62 | 0.6-0.8 | 7050*1625*1280 |

| G250-125 | 5-7 | 250 | 1250*1250*70 | 95 | 0.6-0.8 | 10630*2540*1640 |

| G500-150 | 11-12 | 500 | 1500*1500*78 | 128 | 0.6-0.8 | 14550*2820*1890 |

| G800-200 | 18-20 | 800 | 2000*2000*83 | 114 | 0.6-0.8 | 14700*3500*2390 |

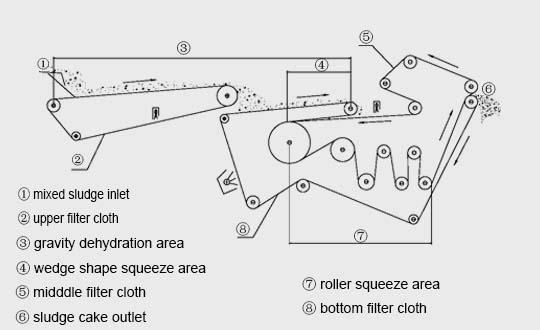

How Belt Filter Press Work

The slurry is dewatered between two tensioned belts. Firstly, moisture is released by gravity at the gravity zone; then slurry moving along the squeezing belts that through a serpentine of decreasing diameter rolls(wedge zone), and extrusion water fall into a collection trough. The pressed sludge is scraped off the belt and collected in a bin.

All clean filtrate and wash water are collected and transferred back for recycling.Typically, slurry needs to be pre-thickened by flocculates before dewatering on a belt filter press.

Befefits & Features

Continuous, automated operation, low energy consumption.

An easily adjustable, variable wedge compression zone that maximizes process rate and performance.

High quality structural frame materials and components for trouble-free, long lasting operation.

Multi-stage dewatering, Compact footprint.

Specifications

| Model | Capacity (t/h) | Belt Width (mm) | Belt Number (pic) | Power (kw) | Overall Size (mm) |

| DY1500 | 6-10 | 1500 | 3 | 11 | 12000*2300*3200 |

| DY2000 | 8-12 | 2000 | 3 | 11 | 12000*2800*3200 |

| DY2500 | 10-16 | 2500 | 3 | 15 | 12000*3300*3200 |

| DY3000 | 12-20 | 3000 | 3 | 15 | 12000*3800*3200 |