Sand making plant is a special production line for producing sand and aggregate materials for construction. In the sand making plant, natural rocks, sandstones, river pebbles and other materials can be processed into artificial sand that meets the requirements of building sand, so as to replace the natural river sand for the buildings and construction industries that need high-quality aggregates.

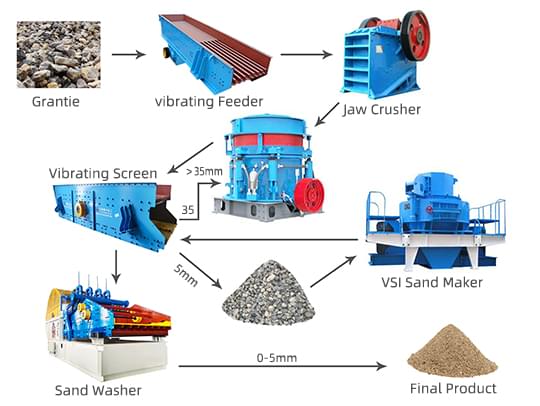

Configuration: vibrating feeder, jaw crusher, impact crusher, vibrating screen, sand washer, belt conveyor and other equipment. In order to meet the different needs of customers, it can be equipped with cone crusher, dust removal equipment, etc.

Materials: suitable for granite, basalt, river pebble, bauxite, cement clinker, quartz, emery, ore, iron ore and other raw materials.

Description: this flow chart is based on the customer's requirement. Actual output can change with the features of raw material, local operation and management conditions.

Workflow: granite raw materials are uniformly sent to jaw crusher for coarse crushing by vibrating feeder, and the coarse crushed stone is sent to cone crusher by belt conveyor for further crushing; The fine crushed stone is sent to the vibrating screen by the belt conveyor for screening. Materials < 5mm are transported to the sand washing equipment for cleaning; Materials > 35mm material is returned to the cone crusher for re crushing; 5-35mm materials are sent to the impact crusher by the belt conveyor for re crushing,thus forming a closed-circuit multiple cycles.

With high automation, less pollution and simple maintenance, the number of employees can be maintained below 3.

The sand production process is carried out under controllable conditions, which are adjustable and controllable, and the quality of finished sand is high.

It not only makes full use of resources, solves the problem of insufficient sand, but also deals with a large number of tailings, increasing wealth.

The use of sand production line can greatly reduce the purchase cost of sand and stone materials by crushing, sand making and grading in one step.

The manufactured sand plant 6 frequently asked questions that may help us to know more about the artificial sand making process.

Artificial sand is sand made by sand making machine and other equipment. Artificial sand can be processed into sand of different specifications and sizes according to different processes.

Because the crushing energy utilization rate is higher than the grinding. More crushing and less grinding can help save energy, but it can not be completely replaced by grinding.

The raw materials of manufactured sand are usually granite, basalt, river pebble, cobble, Andesite, rhyolite, diabase, diorite, sandstone, limestone and so on.

The wheel sand washing machine has the advantages of simple structure, lower failure rate than the spiral sand washing machine. Easy control of fineness modulus and stable quality.

The sieving equipment: cylinder screen, circular vibrating screen, linear vibrating screen, and high-frequency screen. The circular vibrating screen and linear vibrating screen are more common.

The waste concrete, brick, and other industrial waste can make manufactured sand by manufactured sand plant equipment through the process of sorting, cleaning, crushing and screening.

We will provide you with the most suitable probducts

Lzzg's one-stop service chain has reached the professional service mode. Hundreds of skilled and experienced front-line technicians are ready to go at any time to ensure that they can arrive at the production site within 24 hours to bring considerate services to every partner.

Screening is a common process in sand and gravel production lines.

Classification according to the shape and size of different materials, whether it is the pre-screening at the front end or the separation of the finished materials at the end, screening is inseparable.

Read More

It is strongly recommended to add LZZG sand washing machine behind the fine sand for the strict requirement of sand powder content.

The waste water that discharged from sand washer can be recycled by fine sand recycling machine, which not only reduce the environmental pollution, but also increase the sand making production.

Read MorePlease write down your requirement and contact details in the following form. You can also send a message to us by this export@lylzzg.com, we will reply to you within 24 hours.