How to make your own sand sifting machine?

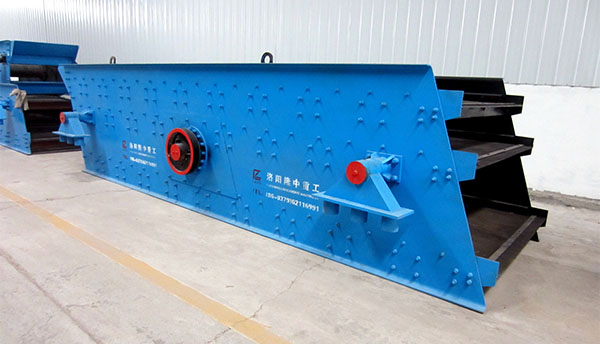

Sand sifting machine is a circular motion, multi-layered, new typevibrating screen, which is a single-axis vibrator. The main shaft fixed on screen box is rotated by motor, and eccentric body mounted on main shaft rotates to generate centrifugal inertia. The screen box that can freely vibrate produces vibration of an approximately circular trajectory. It is quickly advanced, loose, and permeable to complete the screening operation after the material feeding into sieve box.

Then how to make your own sand sifting machine? Sand sifting machine is mainly composed of as followings,

1. Vibrating body—screen box

2. Vibration isolation — support spring group (seat type installation)

3. Rubber spring, spring bearing, eccentric block

4. Power device — single-axis vibration exciter

5. The link device — flexible coupling

6. The drive device — asynchronous motor

7. Relevant random supporting accessories

1. The sieve box is composed of a sieve frame, a sieve plate, a lining plate and the like. The side plate of the sieve for mining vibrating screen is made of high quality steel plate. The side plate and the beam are connected by high-strength bolts or ring groove rivets, and the structure is reasonable and durable;

2. Circular vibrating screen is seated, the adjustment of the screen inclination can be achieved by changing the height of the spring support;

3. The sieve machine adopts metal spring to reduce vibration, which has the characteristics of low noise, long service life, stable over-vibration vibration zone and small dynamic load of each branch of the sieve machine;

4. The drive screen machine adopts the eccentric structure of the whole disassembled vibrator. The structure is simple, the maintenance and replacement are convenient, and the maintenance period is greatly shortened. Overcome the defects of the universal coupling being vulnerable to damage;

5. Flexible coupling, with long service life, small impact on the motor, etc;

6. The transmission part has an intermediate transition bearing seat. The application of the intermediate transition bearing seat effectively protects the motor and prolongs the service life of the motor. The motor is installed on the left side of the screen frame and can also be installed on the right side of the screen frame;

7. It can be matched with the feeding box. The application of the feeding box increases the effective screening area of the vibrating screen and prolongs the service life of the feeding end screen.

And accuracy control in the production process is the core to ensure the quality of production. The installation and commissioning of each part must be completed in accordance with the process requirements and drawing accuracy requirements. For vibrating screen equipment, the welding deformation is too large to be a technical point to be improved. Mainly due to the deformation of the steel welding; the longitudinal beam of the screen frame, the feed box, the tailgate, and the connecting plates on both sides of the main screen of the linear screen with the box vibrator have this problem. The enterprise generally adopts a single manual arc welding. This method is often used for small parts welding, resulting in low efficiency and clean welding of the weld skin, which is easy to form defects such as slag inclusion.

Send Message

Please write down your requirement and contact details in the following form. You can also send a message to us by this email export@lylzzg.com, we will reply to you within 24 hours.